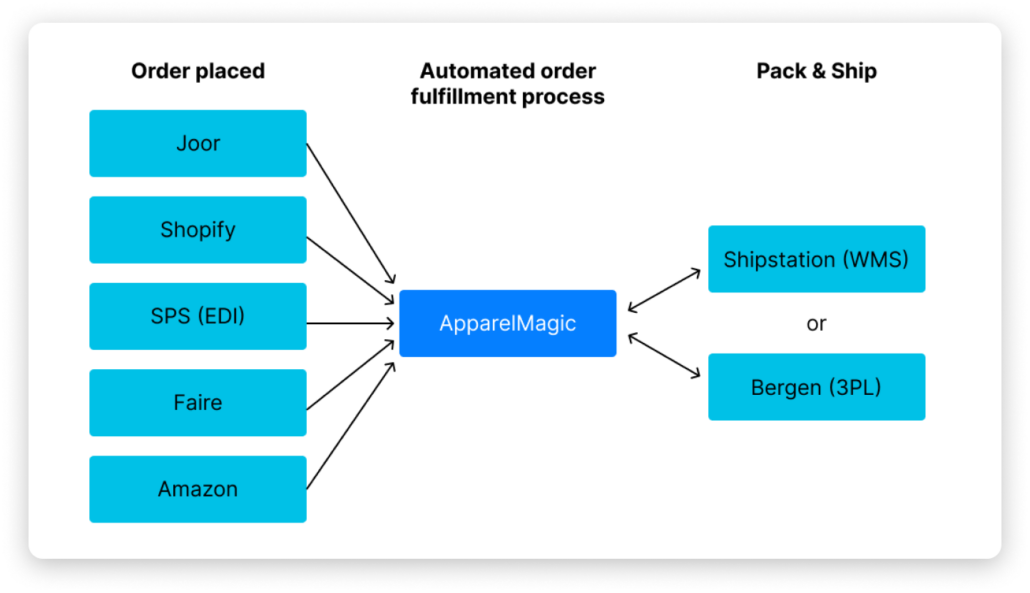

Print-on-demand is growing fast, and if you’re a wholesaler, juggling spreadsheets and scattered design files just doesn’t cut it anymore. You need one system that connects your artwork, materials, production, orders, and fulfillment from start to finish. That’s what ApparelMagic delivers.

It lets you treat emblems as actual inventory, set up clear workflows for each customization, and automate your purchasing and manufacturing. Everything runs in one simple browser-based platform, helping you stay organized and grow your business without wasting time.

Let’s take a closer look!

1. Configure & Price Your Emblems

Under Products > Emblems, you can now create each custom logo, patch, or transfer as its own “style.” Emblems include:

- Reference Code and Default Price:

Think of your emblem like its own SKU. This keeps your pricing and reporting accurate and easy to track.

- Color and Size Matrix:

By default, emblems come in one color and size. But if you have different color versions or patch sizes, you can add a full matrix to cover all the options.

- Buyer Filters and Required Notes:

You can limit certain emblems to specific customers, like team orders. You can also make sure users enter important details, such as player names or serial numbers, before they can add the item to an order.

2. Define Placement Options for Your Styles

If you’re offering on-garment customization, you can assign where each emblem goes. Use the Placements section in the style record or import them in bulk under Products > Emblems > Style Emblem Placements.

- Name and Image:

Label each area, like “Left Chest” or “Back Yoke,” and add a visual so buyers know exactly where the emblem will go.

- Placement Price:

Add an extra charge if needed. This could cover the cost of placing the emblem in a tricky spot or adding a premium finish.

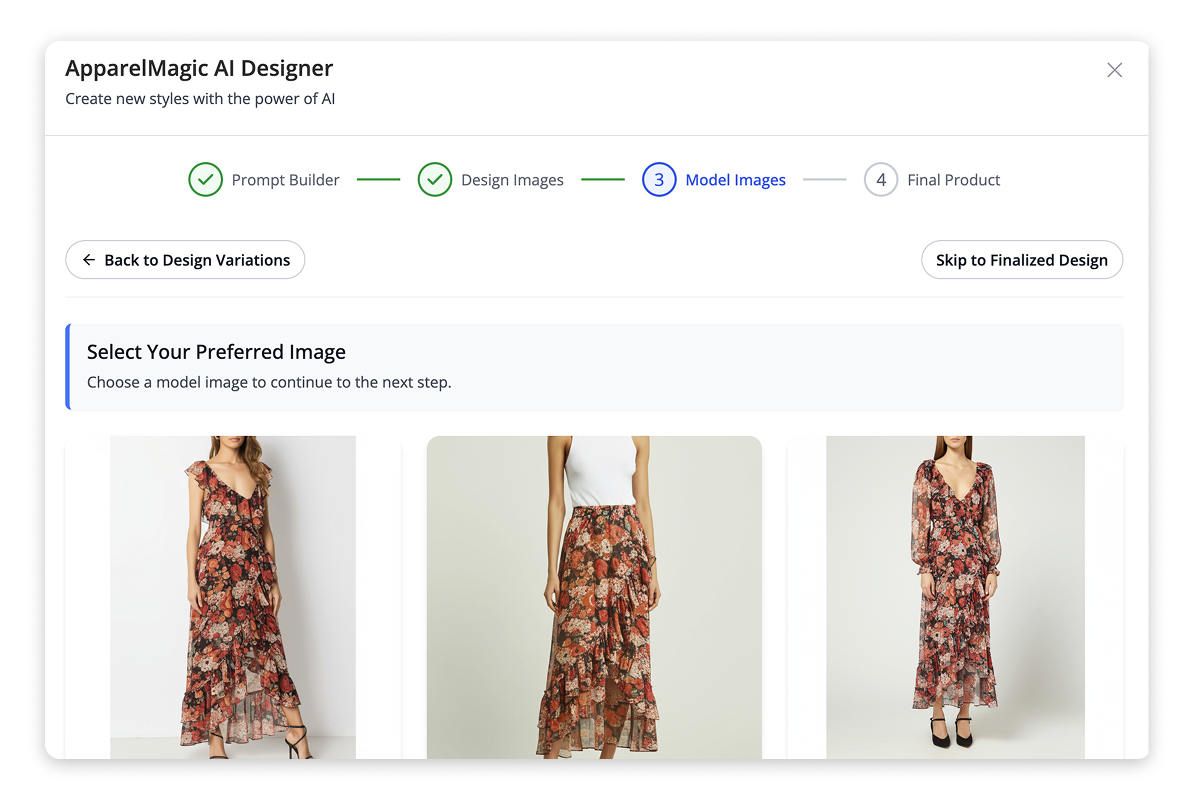

3. Sell Custom Styles with Ease

Order Entry UI: When entering an order manually, just click the green emblem icon on any line item. A step-by-step tool opens where you pick the finish, emblem, placement, and add any required notes. Everything shows up clearly on the order and in the confirmation email.

B2B Storefront: Wholesale buyers follow the same easy steps on your branded portal. If you’ve set up product restrictions by customer, they’ll only see the emblems and placements they’re allowed to order. It keeps the process smooth and the orders accurate.

4. Automate Purchasing & Production

As orders come in, ApparelMagic turns them into clear, actionable tasks so nothing slips through the cracks.

- Order-Driven Projects and POs:

Tag specific order lines under Production > Manufacturing > Order Drive Project or Production > Purchase Orders. The system pulls in the bill of materials (BOM) and steps for each style, then creates work orders or purchase orders (POs) in seconds.

- Demand-Driven Workflows:

When sales exceed on-hand or WIP quantities, use Demand Driven Project or Demand Driven PO to satisfy backorders automatically, keeping you agile during seasonal surges.

- Manual and WIP Projects:

For bespoke runs, Production > Manufacturing > Manual Project lets you build projects from scratch, calculate requirements, and generate POs for any missing materials.

5. Track Performance and Fine-Tune Your Process

Real-Time WIP and Available to Sell: As you run production, your numbers stay up to date. With Work-In-Progress and Available-to-Sell metrics you’ll always know what’s in progress and what’s ready to sell, so you don’t run out of a popular patch or blank.

Emblem Reporting: Use filters like “Is Emblem” in your style reports, or drill into Order Item Analysis and Invoice Item Analysis to see which logos and placements drive your highest margins. The data is there to help you make smarter decisions every step of the way.

Keep Your Operations in Step with the Season

Whether you’re planning a late-summer trunk show or prepping for a fall product launch, ApparelMagic keeps everything moving. Emblems, blanks, and production steps all flow in one system, from the first order to final delivery. No more juggling spreadsheets or chasing down data across tools.

If you’re ready to take the guesswork out of print-on-demand, schedule a demo today. ApparelMagic brings your ERP, PLM, CRM, and production tools together so you can run smarter all year long.