Industry News

Most Popular

What Is an Apparel Trunk Show and Why It Matters

Trunk shows might sound fancy, but they’re just smart business. In fashion, they give brands a chance to skip the middleman and go straight to the customer or buyer. You show off the next season’s collection, get real feedback, and

Apparel ERP That Integrates with Shopify

As fashion brands grow beyond one sales channel, keeping eCommerce, wholesale, and in-store operations aligned becomes critical. An ERP that connects directly with Shopify makes sure your product info, orders, inventory, and financials all flow together. That way, you spend

Streamline processes & increase productivity by 60%

Explore more content

Fashion Calendar Explained: When Do Fall Clothes Come Out

As Fall 2025 approaches, understanding the fashion calendar is crucial for manufacturers, buyers, and retailers. Knowing when fall clothes come out can help you prepare for the season and start planning for it. This guide outlines key milestones during the

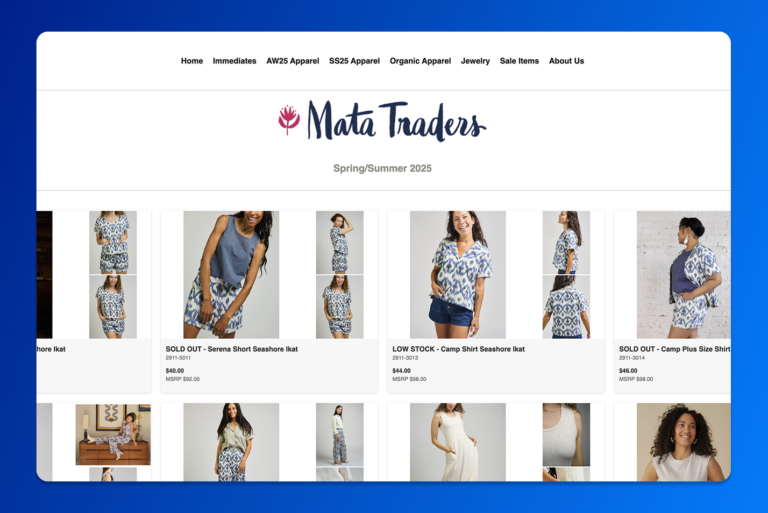

Building a Wholesale Website: What Apparel Brands Need to Know

In the fast-paced world of wholesale apparel purchasing, buyers have little patience for complicated websites or convoluted browsing experiences. The modern retail buyer typically manages multiple brands and works under tight deadlines. Your wholesale website’s navigation and search functionality can

10 Lessons From an Apparel Startup That Sold Half a Million Units in 18 Months

What every apparel founder should steal from Jack and Sage’s playbook. You don’t go from zero to nearly 500,000 units sold in 600 stores in under two years by luck. That kind of growth takes strategy, guts, and a bit

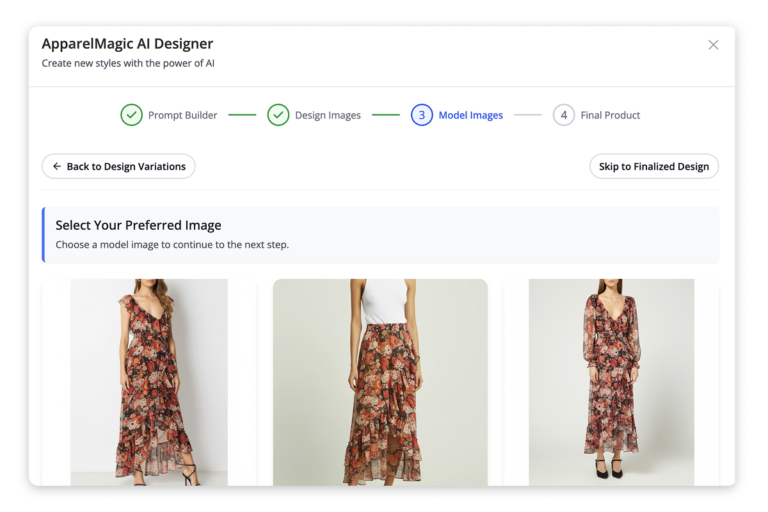

Design by prompt: ApparelMagic Launches AI Designer, the First Generative Design Engine Built into an Apparel ERP/PLM

Take pre‑orders before a single sample is cut. ApparelMagic’s new AI Designer collapses weeks of sketching, tech‑pack prep, and prototype revisions into minutes, letting brands move from idea to photorealistic product shots inside the same cloud platform they already use

How ApparelMagic Helped Kanine Scale a Global Pet Fashion Empire

The Challenge In early 2022, Kanine was a bold idea just getting started — a premium pet apparel company looking to bring fashion-forward products to furry friends around the world. Within their first year, the team was already making waves,

Jack and Sage: Powered by ApparelMagic from Day One

Challenge When Alex Biegler launched Jack and Sage, he set out to reinvent logowear. Drawing from his experience founding and selling a successful custom headwear company, Alex envisioned an apparel brand that blended functional outdoor gear with bold, high-quality design,

How ApparelMagic Empowers Ash and Eden’s Mission in Sustainable Fashion

Challenge: Bridging Traditional Craftsmanship with Modern Business Operations Ash and Eden, a brand under the Be You Be One umbrella, is redefining sustainable fashion by preserving traditional artisan techniques while adapting them for modern markets. Collaborating with artisans across India,

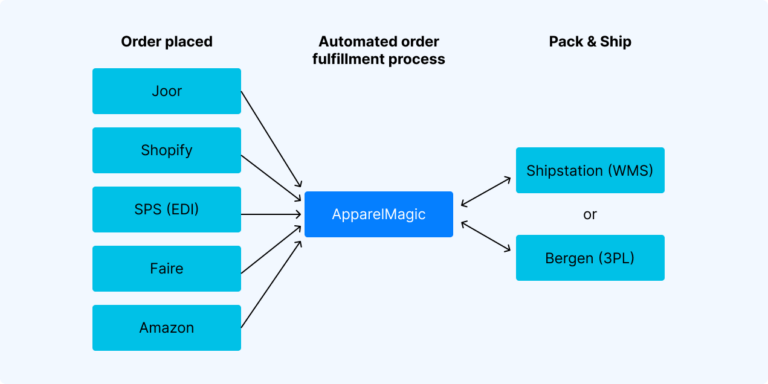

Automating Order Fulfillment with a Fashion ERP

Operational efficiency can be the difference between growth and stagnation for fashion brands. While creativity and design often take center stage, the back-end processes, particularly order fulfillment, can make or break your business. That’s where a specialized fashion ERP comes

Triarchy’s Global Market Expansion with ApparelMagic

Challenge Triarchy, a sustainable fashion brand, has made waves in the denim industry with its innovative plastic-free stretch denim, the first of its kind. The brand, led by designer Adam Taubenfligel, is committed to sustainability, offering products made from natural

View Pricing →

Discover our competitive pricing plans tailored to fit your business needs.

About the Company →

Learn about our journey to becoming the leading provider of fashion and apparel management software.