Struggling to manage product returns efficiently? Effective returns management solutions can transform a cumbersome process into a streamlined operation. This article will guide you through building a sustainable returns management system for your apparel business, ensuring customer satisfaction and operational efficiency.

Understanding the Importance of Returns Management in Apparel

Returns management goes beyond just handling returned items; it significantly impacts customer satisfaction and loyalty. When customers know they can return items easily and without hassle, they are more likely to make a purchase and return for future buys, fostering a sense of trust and reliability in your brand. An effective returns process can thus turn a potentially negative experience into a positive one, enhancing overall customer satisfaction.

The financial implications of returns are another critical aspect to consider. Returns can be costly due to the need for additional logistics, restocking, and potential markdowns on returned items. However, with a well-structured returns management system, these costs can be mitigated. Efficient managing returns can also prevent revenue loss by reducing the time products spend out of circulation and ensuring they are quickly available for resale.

Environmental considerations must not be overlooked. The apparel industry is notorious for its environmental footprint, and returns can exacerbate this issue if not managed sustainably. Incorporating eco-friendly practices, like refurbishing and reselling items or recycling unsellable products, significantly reduces environmental impact and appeals to environmentally conscious consumers.

Implementing a User-Friendly Returns Policy

User-friendly returns policy solutions are crucial for effective returns management. Clear and transparent return guidelines set customer expectations and reduce confusion. Customers should know exactly what to do if they need to return an item, including timeframes, conditions, and any costs involved. This transparency not only enhances customer satisfaction but also streamlines the entire returns process.

Accommodating various customer needs requires flexibility. Offering multiple return options, like in-store returns, mail-in returns, online returns, and drop-off points, significantly improves the customer experience. Additionally, providing options for exchanges, refunds, or even bonus credit can cater to different preferences and encourage customer loyalty to continue shopping with your brand.

Keeping customers informed throughout the refund process requires effective communication. Automated emails and notifications update customers on the status of their return request, ensuring they feel valued and informed. Incorporating QR codes for easy tracking and return initiation can further simplify the process, making it more convenient for both customers and your returns management team.

Leveraging Technology for Efficient Returns Processing

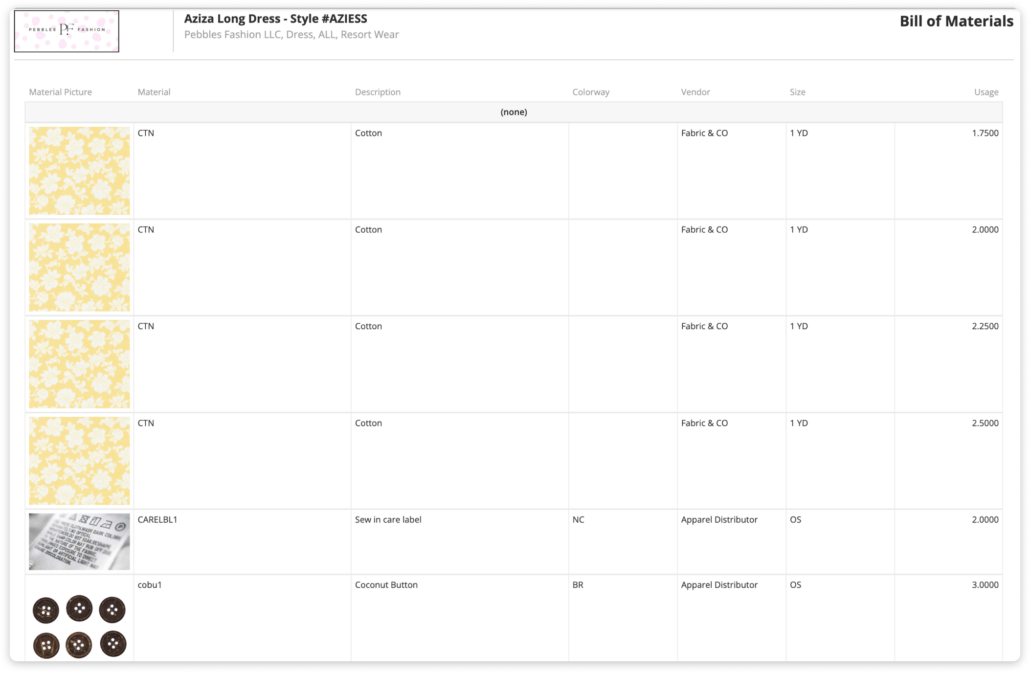

In today’s digital age, leveraging technology is essential for an efficient returns process. Utilizing ERP systems like ApparelMagic allows for real-time tracking and inventory updates, ensuring that returned items are processed and restocked promptly. This not only saves time but also optimizes inventory management, reducing the risk of stockouts or overstock situations.

Another critical factor is integration with e-commerce platforms. Seamless integration ensures a smooth and hassle-free returns process for customers, from initiating a return to receiving a refund or exchange. This also allows for better data synchronization across systems, providing a comprehensive view of returns data and facilitating more informed decision-making.

Automation revolutionizes returns management. Automating return authorization and processing reduces manual workload and errors, leading to faster and more cost-effective returns handling. This includes setting up automated rules for return approvals, which can streamline operations and ensure consistency in handling returns.

The best returns management software incorporates these features, providing unique advantages like saving time and money while enhancing the overall returns process through a returns management solution.

The Importance of a Returns Integration

One of the leading platforms in returns management, Loop Returns, offers a comprehensive and user-friendly solution for businesses looking to streamline their returns processes. Designed specifically for e-commerce businesses, Loop Returns integrates seamlessly with ApparelMagic, enabling a smooth, hassle-free returns experience for both customers and business operators.

With features like automated return approvals, real-time inventory updates, and advanced analytics, Loop Returns simplifies the returns process. It also promotes sustainability by encouraging exchanges over refunds, reducing waste and fostering a circular economy. Businesses can use the platform to:

- Enhance customer experience: Offer quick and transparent return options with automated tracking and communication.

- Boost efficiency: Reduce manual errors with streamlined workflows and integration capabilities.

- Promote sustainability: Encourage customers to exchange items instead of opting for refunds, minimizing environmental impact.

- Leverage data: Access detailed insights to understand return patterns and improve product offerings.

Incorporating Loop Returns into your apparel business is a step toward building a sustainable and efficient returns management system that aligns with modern customer expectations and operational excellence.

Analyzing Return Data to Improve Products and Processes

Analyzing return data is a powerful tool for improving both products and processes. By identifying common reasons for returns, businesses can gain valuable insights into product performance and quality issues. This data can highlight recurring defects or design flaws that need to be addressed, ultimately leading to better product offerings and reduced return rates.

Data analytics informs product development and inventory management. Understanding patterns in returns helps businesses make informed decisions about which products to stock and how to manage inventory levels. This proactive approach can lead to more efficient operations and better alignment with customer preferences.

Feedback loops are vital for continuous improvement. Using returns data to refine products and processes enhances customer satisfaction and drives growth. This involves regularly reviewing return reasons and customer feedback, and making necessary adjustments to products, policies, and procedures.

The value of returns data lies in its ability to provide actionable insights that can be leveraged for long-term success.

Sustainable Practices in Returns Management

Sustainability in returns management is both responsible and strategic. Refurbishing and reselling returned items reduces waste and recaptures value from products that might otherwise be discarded. This practice not only supports environmental sustainability but also opens up new revenue streams.

Donating or recycling unsellable products is another effective strategy. Items that cannot be resold can still be used through donations to charitable organizations or recycling programs. This reduces the environmental impact of returned items and demonstrates a commitment to corporate social responsibility.

Reverse logistics is essential for sustainable returns management. Optimizing return shipments minimizes carbon footprint and reduces costs. Implementing best practices in reverse logistics ensures that the entire returns process is as efficient and eco-friendly as possible, aligning with broader sustainability goals.

Training Staff for Effective Returns Handling

Effective returns management solutions revolve around properly training your staff. Educating employees on returns policies and procedures equips them to manage returns efficiently and consistently. This includes understanding the different return reasons and how to process each type of return accurately.

Empowering customer service teams is crucial for smooth returns management. As the first point of contact for return requests, their ability to handle inquiries and issues promptly and professionally significantly impacts customer satisfaction. Training them on the nuances of the returns process and providing them with the necessary tools and support is crucial.

Warehouse staff play a vital role in the returns process. Ensuring they can process returns promptly and accurately is key to maintaining an efficient returns management system. This includes training on how to inspect returned items, update inventory systems, and prepare items for resale or disposal.

Continuous Monitoring and Optimization of the Returns Process

Continuous monitoring and optimization are necessary for an effective returns process. Regularly reviewing and updating returns policies keeps them relevant and aligned with industry standards and customer expectations. This proactive approach helps in processing returns and addressing any gaps or inefficiencies in the process.

Monitoring key performance indicators (KPIs) related to returns identifies areas of improvement. Metrics like return rate, processing time, and customer satisfaction provide valuable insights into the effectiveness of your returns management system. By analyzing these KPIs, businesses can make data-driven decisions to optimize their returns processes.

Adapting to industry trends and customer expectations is vital for staying competitive. The apparel industry and customer preferences are constantly evolving. Monitoring these trends and adjusting your returns process accordingly helps meet customer demands and enhances their overall experience.

Wrap Up

Building a sustainable product returns management system is crucial for the success of any apparel business. From understanding the importance of returns management to implementing user-friendly policies, leveraging technology, and adopting sustainable practices, every aspect plays a vital role in creating an efficient and customer-friendly returns process.

By continuously monitoring and optimizing the returns process, and training staff effectively, businesses can ensure that their returns management system not only meets but exceeds customer expectations. Adopting these strategies will help in reducing costs, enhancing customer loyalty, and promoting environmental sustainability. It’s time to turn returns management into a competitive advantage.