What every apparel founder should steal from Jack and Sage’s playbook. You don’t go from zero to nearly 500,000 units sold in 600 stores in under two years by luck. That kind of growth takes strategy, guts, and a bit

News from ApparelMagic clients

Around the world, the biggest names in fashion choose ApparelMagic

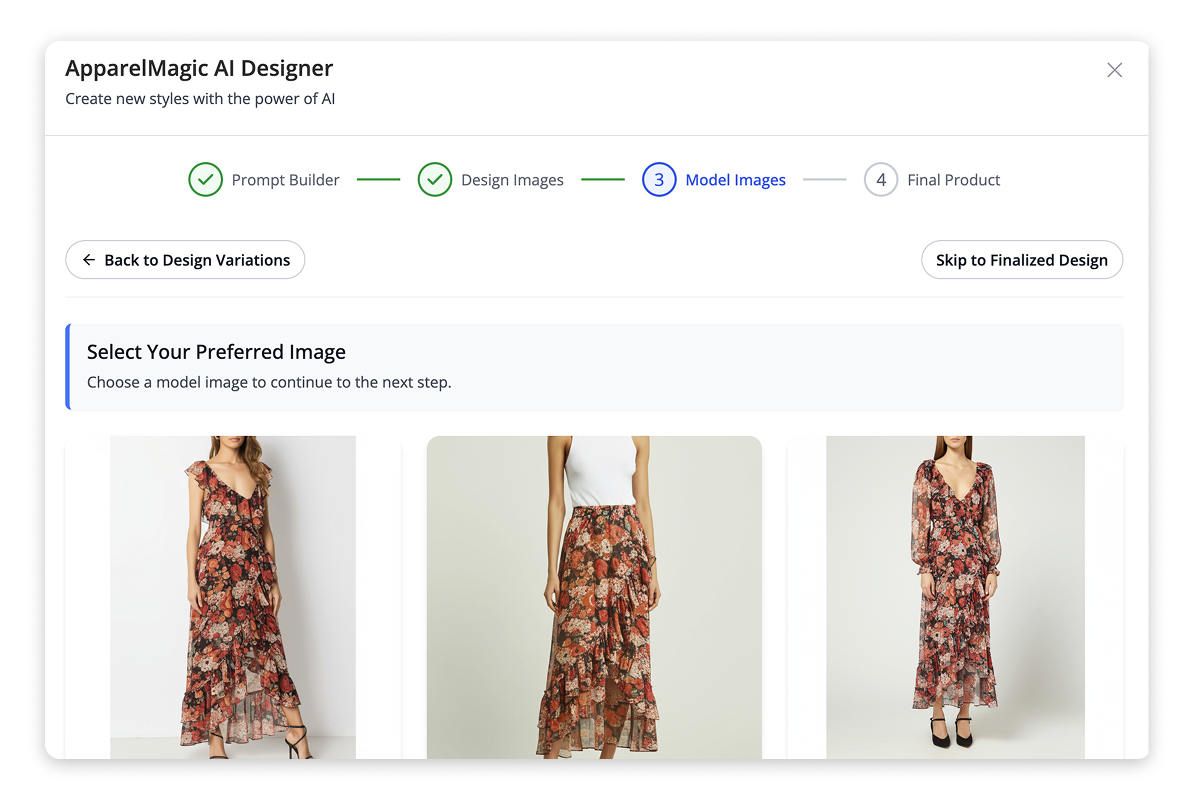

Design by prompt: ApparelMagic Launches AI Designer, the First Generative Design Engine Built into an Apparel ERP/PLM

Take pre‑orders before a single sample is cut. ApparelMagic’s new AI Designer collapses weeks of sketching, tech‑pack prep, and prototype revisions into minutes, letting brands move from idea to photorealistic product shots inside the same cloud platform they already use

How ApparelMagic Helped Kanine Scale a Global Pet Fashion Empire

The Challenge In early 2022, Kanine was a bold idea just getting started — a premium pet apparel company looking to bring fashion-forward products to furry friends around the world. Within their first year, the team was already making waves,

Jack and Sage: Powered by ApparelMagic from Day One

Challenge When Alex Biegler launched Jack and Sage, he set out to reinvent logowear. Drawing from his experience founding and selling a successful custom headwear company, Alex envisioned an apparel brand that blended functional outdoor gear with bold, high-quality design,

How ApparelMagic Empowers Ash and Eden’s Mission in Sustainable Fashion

Challenge: Bridging Traditional Craftsmanship with Modern Business Operations Ash and Eden, a brand under the Be You Be One umbrella, is redefining sustainable fashion by preserving traditional artisan techniques while adapting them for modern markets. Collaborating with artisans across India,

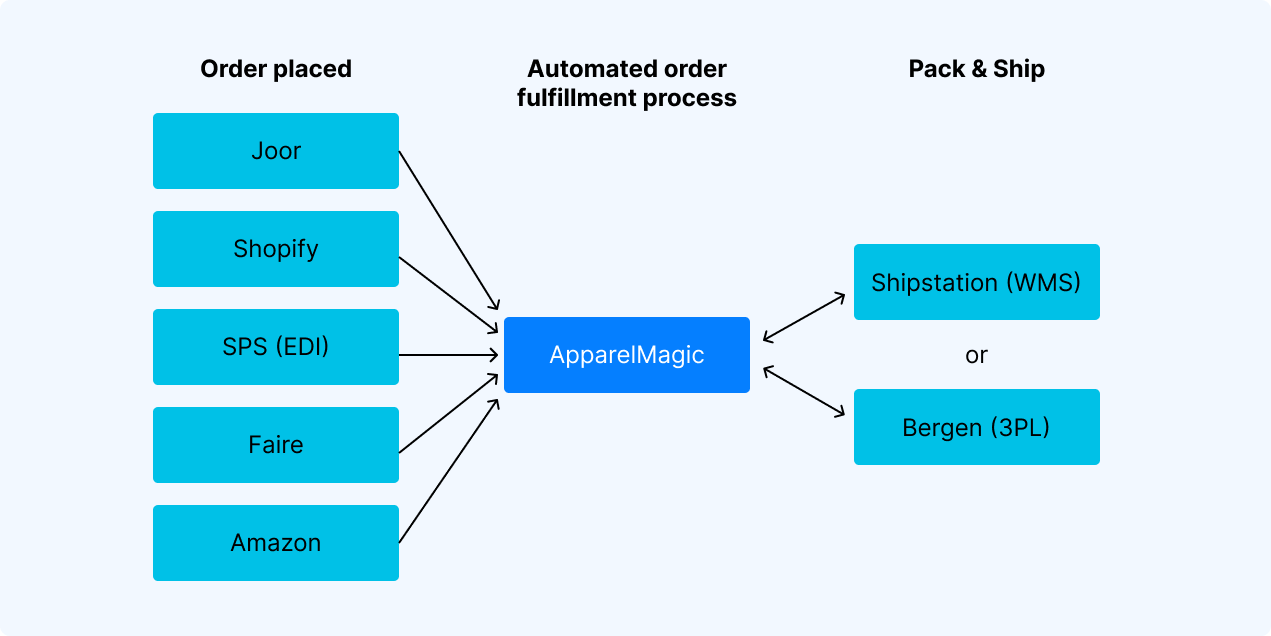

Automating Order Fulfillment with a Fashion ERP

Operational efficiency can be the difference between growth and stagnation for fashion brands. While creativity and design often take center stage, the back-end processes, particularly order fulfillment, can make or break your business. That’s where a specialized fashion ERP comes

Triarchy’s Global Market Expansion with ApparelMagic

Challenge Triarchy, a sustainable fashion brand, has made waves in the denim industry with its innovative plastic-free stretch denim, the first of its kind. The brand, led by designer Adam Taubenfligel, is committed to sustainability, offering products made from natural

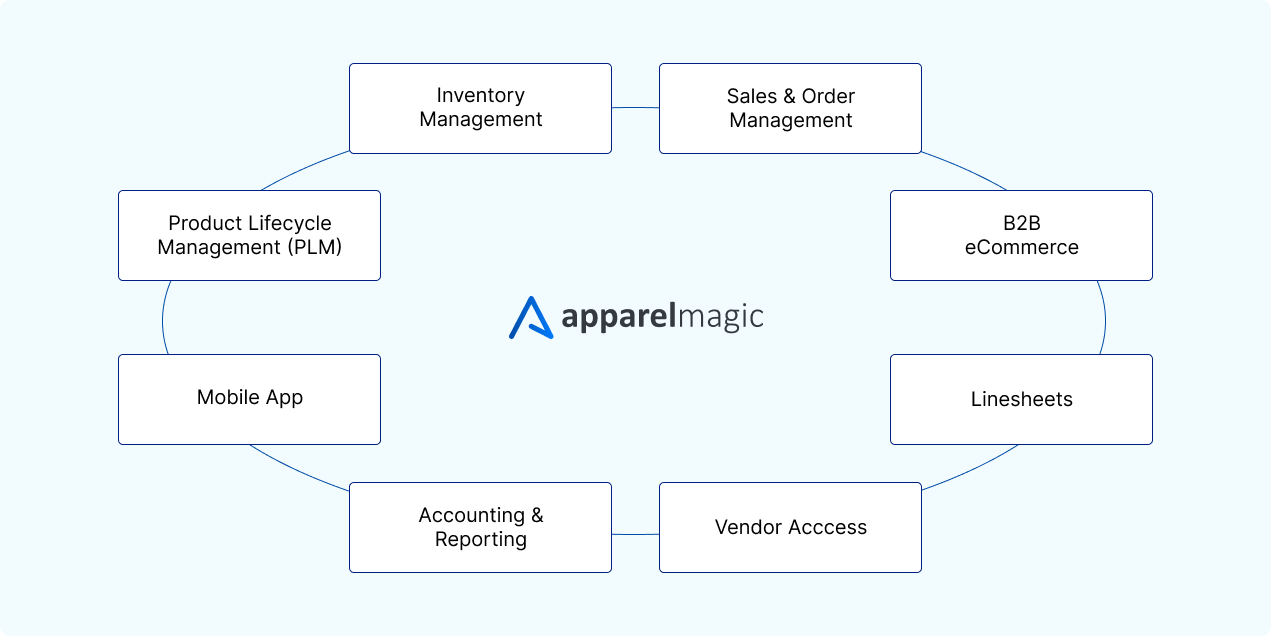

Tired of Using Multiple Platforms to Manage Your Apparel Brand?

In the competitive world of fashion, efficiency is key. Yet many apparel, footwear, and accessory brands find themselves juggling multiple applications and subscriptions – one for design, another for inventory, and yet another for order fulfillment. While this patchwork approach