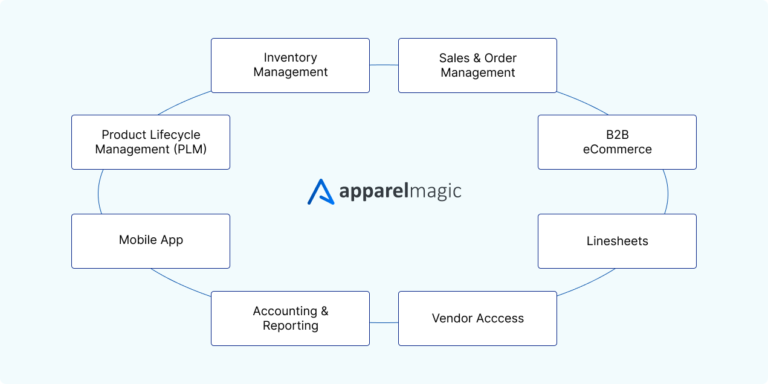

PLM stands for product lifecycle management, which is the process of managing a product’s entire lifecycle from conception through design, manufacture, service, and disposal. PLM optimizes manufacturing, enables better team collaboration, and reduces errors, ultimately saving money and time, a strategy that is critical for all companies that manufacture goods.

Nowadays, product lifecycle management usually refers to PLM software that serves as the backbone for all product activities from inception to retail. Product lifecycle management software enables companies to update their business operations, increase innovation, make collaboration easier, and expedite product development by integrating products, people, and actions across the whole product lifecycle as a single source of truth.

In this post, we’re explaining how product lifecycle management software works and how it can improve the efficiency of your business.

Image by boutiquegirlish21 from Pixabay

How Does PLM System Work?

Product lifecycle management brings together the various employees and departments involved in a product’s development and streamlines their activities with the purpose of manufacturing a product that is profitable and outperforms its competitors.

A PLM system provides designers and engineers with real time access to the vital data they require and insight into external sources of information such as customer feedback on current products and product performance data. Beyond design and engineering, a product lifecycle management system can help other teams in an organization. It can give business stakeholders and/or suppliers a “single source of truth” for easy feedback delivery early in the product development process.

PLM systems are considered one of the cornerstones of a manufacturing company’s information technology framework, along with internal resources (enterprise resource planning – ERP), supplier relationships (supply chain management – SCM), and management of client communications (customer relationship management – CRM).

Phases of Product Development

There’s no industry standard when it comes to describing the phases of product development. The five phases below, however, constitute a typical development cycle.

- Ideation and design: Defining a product’s requirements based on criteria such as competitive analysis, market gaps, or consumer requirements.

- Product development: The product’s detailed design will be prepared at this phase. Analysis and validation of the planned product, as well as the development of prototype and testing, are all part of this stage too. This provides vital feedback on how the product is utilized and whether any improvements will be required.

- Production and launch: The design and other elements are tweaked based on the received feedback to create an improved version for the market. The new product’s production is ramped up, then launched and distributed to the market.

- Product maturity: Your product is now available to consumers. This is the period during which support and service are provided. You may need to make packaging or marketing changes at this phase.

- Product decline/retirement: Over time, your product might pass peak demand and it may be time to devise an exit strategy or reinvent the product in order to uncover areas of potential, such as new markets or iterations that can improve your product or withdraw the product altogether.

How to Use PLM in Your Business?

A product lifecycle management system provides a multitude of functions and application cases. Some of the most common uses are listed below.

Design. PLM software allows you to design in real time while simultaneously adding new data to the system. It provides visibility into the product design process for all business stakeholders. Because the final product is created based on customer insight, this process reduces time-to-market. As a result, your business might see enhanced innovation and increased revenue.

Supply chain. As businesses embrace new business models and spread on a global scale, supply chain strategies have to alter as well. Companies can streamline the supply chain with product management lifecycle software, allowing businesses to manage every single component of the process to meet the needs of buyers and any regulation requirements.

Production. Because of its collaborative nature, a product lifecycle management tool can help you shorten time to market while saving expenses. By providing real time traceability during the manufacturing process, it allows external partners and internal teams to follow the correct workflow.

Distribution. Product information management (PIM) is the phase that occurs after a product has been manufactured. Integration with a PIM system allows a PLM tool to send information about distribution and service items to the appropriate stakeholders. PLM is a useful system for communicating the most up-to-date product data in a timely way so that the product may move from engineering to market.

A Bill of Materials is a list of goods required to make a product, and it is an important part of a product lifecycle management solution. By connecting in real time adequate sourcing information, production details, regulatory compliance, and other information, organizations can cooperate from the point of product creation to manufacturing.

Product portfolio management is a data-driven approach that lets manufacturers and retailers determine which items should stay, increase or reduce costs, or need updating in order to satisfy consumer needs. Because PLM technologies provide full insight and a thorough perspective of the entire lifecycle and development process of the product, firms may efficiently optimize product portfolios on a broad scale.

Engineer-to-Order. Because customer involvement is critical for product needs, ETO necessitates thorough collaboration. A product lifecycle management tool for engineer-to-order is a system that allows you to communicate information about the product with the engineers, sales team, and operations team. Market statistics, consumer trends, and client satisfaction are all key components of product success, and this one source of truth gives access to all external and internal stakeholders. Data gathered from suppliers, manufacturers, internal stakeholders, and consumers could then be used to reduce time-to-market, improve and enhance the efficiency of employees, and speed up product development.

Image by Orna Wachman from Pixabay

What Are The Benefits Of Using A PLM Solution?

Many companies are transforming the way they design, manufacture, and sell goods by adopting technology like product lifecycle management software. Let’s take a closer look at the main advantages of using a PLM solution:

- Improved communication and collaboration. Real time data and process capabilities are especially critical for multinational companies working with external partners and internal teams dispersed across different locations around the world. A PLM system allows all parties involved in the product development to make changes in real time and supports interfaces with external databases, resulting in a “single source of truth” which helps improve product launch success rates, boost productivity, and increase sales.

- Reduction of errors. Tracking all product information can get difficult when using multiple applications such as Excel, email, Dropbox, and PowerPoint. A PLM tool simplifies workflow insight into all product-related data, reducing the number of meetings, phone calls, and emails, together with the time spent searching and updating information.

- Reduced time to market: Companies can get products to market faster by using PLM to gain access to product information, which simplifies business processes, improves supply chain collaboration, and boosts decision-making capabilities. Businesses can identify time-consuming and expensive risks and take steps to keep products flowing by utilizing this visibility.

- Enhanced product quality. Product lifecycle management software makes it straightforward and quick to regulate and manage all of the facts that have an impact on overall product quality. Manufacturers can use PLM to automate all of the processes and procedures that are required to maintain product quality and customer satisfaction.

- Improved sustainability. PLM technologies can help you achieve environmental sustainability goals and help with the challenges of waste management by enabling closed-loop product development.

- Improved compliance. Collaboration in real time helps businesses with concerns like regulation issues. Factory audits, compliance issues, quality assurance, and vendor scoring all require a simple solution, and that’s exactly what effective product management lifecycle software provides.

- Increased revenue: Businesses can use product lifecycle management software to rapidly and correctly calculate the relationships between pricing, cost, and profit in order to meet sales targets. PLM has also proved to save companies money on things like production expenses, lead time, inventory prices, and product costs.

The Bottom Line

Technology can offer fashion businesses a great return on investment, but that can only happen if they focus on the business benefits. A single source to manage all data and operations is critical for organizations and manufacturers who need to create, source, produce and distribute goods. An end-to-end PLM solution gives you visibility into your supply chain and the capacity to handle product data from the design phase to after-sales service.

With the right PLM solution, you can streamline operations, launch new products quickly and cost-effectively, eliminate inefficiencies, reduce compliance risks, and focus on what matters most—growing your business. Best of all, choosing PLM software with industry-specific capabilities allows you to reap these benefits faster and with fewer customizations to ensure both long-term and short-term business success.