Being able to complete every order efficiently is a requirement of the retail industry. The goal of a warehouse management system (WMS) is to ensure that materials and products are moved through warehouses in the most effective and economical manner possible. A WMS manages a variety of tasks that make this movement possible, such as inventory tracking, receiving, picking, and storage. Additionally, a WMS offers real-time visibility into a company’s inventory at any place and time, regardless of whether it is in transit or at a facility.

In this article, learn about the key features of inventory warehouse management systems, why warehouse inventory management is important, and industry best practices you can implement.

Image by Jens P. Raak from Pixabay

Why Use a Warehouse Management System

Businesses that employ warehouse management solutions have increased supply chain management optimization. They keep track of stored products to make inbound and outbound shipments more efficient. This way, they can maintain the supply chain movement.

A WMS can help you speed up order fulfillment and keep track of what’s selling well. If you can see which products are frequently leaving your warehouse, you’ll be able to find new ways to optimize its layout and organization for maximum efficiency. When raw materials arrive, you may keep track of them and ensure that they are placed where they would be most useful for manufacturing and stocking. Instead of being at the other end of the room, the best-selling items can be close to the packing area or loading dock.

Some of the benefits that you might experience when using an inventory system for warehouse management include reduced labor costs due to more effective labor allocation, streamlined warehouse operations, improved inventory accuracy, precise demand forecasting, increased warehouse security and safety, an improved configuration for the layout of the warehouse, and improved supplier relationships and customer service.

Types of Warehouse Management Systems

The type of WMS you choose will depend on how you organize your warehouse’s priorities. Start by determining what features you require in their system and how much you are willing to invest. After that, you may ask a supplier for further details about how they can efficiently customize a warehouse inventory system for your company. Here are the options you can choose from:

Cloud-Based vs. On-Premise

An on-premises warehouse management solution is one where you are in charge of hosting and maintaining the software and hardware connected to your system. This allows you total control over aspects like security and uptime, but because you are in charge of every component, it also has a high upfront cost. You will also need to keep your inventory warehouse inventory system regularly maintained.

A cloud-based warehouse management system, on the other hand, is hosted on a remote server and is often charged on a subscription basis. Software updates and bug fixes are taken care of by the vendor, and when you sign up, you often receive a level of service uptime that is guaranteed.

Standalone Vs. Integrated

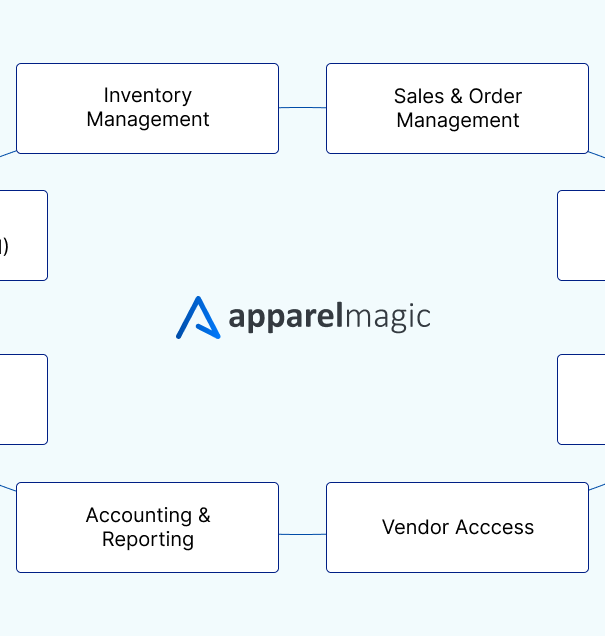

Software with several features that is primarily used for warehouse management is known as a standalone inventory system for warehouse management. As a result, it might only be partially usable for other facets of your company, such as accounting or inventory. This kind of warehouse management system can include extensive reporting tools that will assist you in leveling up your warehouse because it is designed specifically for warehouse management.

The addition of an integrated warehouse inventory system is typically offered by your existing ERP supplier. ERP systems control accounting, stock management, and invoice generation. The warehouse inventory system receives the orders, controls inventory, and oversees product receiving and shipment. It is much simpler to keep track of which orders are the greatest ones to invest money in when everything can integrate into a single system.

Features of Warehouse Management Systems

Warehouse management software products share a lot of characteristics. These are a few of them:

- Warehouse organization. Organizations can adjust workflow and picking logic through warehouse design, ensuring that the distribution center is set up for the best possible inventory distribution. Bin slotting is established by the warehouse management system to maximize storage space and take seasonal inventory variations into account.

- Inventory tracking allows for sophisticated tracking and Automatic Identification and Data Capture (AIDC) technologies, such as barcode scanners and Radio-Frequency Identification (RFID), to ensure that products are quickly located when they need to be moved.

- Receiving and storing, which enables storage and retrieval of inventory and aid warehouse workers in finding items more quickly and easily.

- Picking and packing products, including batch, wave, and zone picking. Additionally, lot task interleaving and lot zoning features can be used by warehouse staff to direct picking-and-packing tasks in the most effective manner.

- Shipping management. This feature enables the warehouse management system to create packing lists and invoices for shipments, notify receivers of shipments in advance and send bills of lading of the shipment in advance.

- Dock and yard management helps truck drivers find the appropriate loading docks when they enter a warehouse. Cross-docking and other logistic tasks are made possible by more sophisticated use of yard and dock management.

- Labor management. Utilizing KPIs (key performance indicators) that show whether workers perform above or below expectations with an aim to aid warehouse managers in keeping an eye on employees’ performance.

- Reporting assists managers in evaluating the effectiveness of warehouse processes and identifying potential improvement areas.

Image by icondigital from Pixabay

Tips For Improving Your Warehouse Inventory Management System

Ensure that the following best practices and procedures are in place when designing your storage facility in order to move goods quickly, maximize efficiency, and increase profit margins:

1. Determine Your Warehouse Layout

When a product is sold or needs to be transferred, your warehouse’s layout will either impede or aid your staff in picking, packing, and shipping.

How you organize your warehouse will largely depend on the goods you store. A warehouse that houses massive machinery, for instance, might have designated zones but is not very likely to have aisles and bins like a storage facility that houses smaller retail goods.

When designing the layout of your storage facility, consider how warehouse employees will be moving around the warehouse floor. Organizing warehouses into lots or zones and numbering bins and aisles might make it easier for warehouse personnel to move throughout the warehouse.

2. Appoint a Warehouse Manager

One of the most important steps when it comes to running a productive storage facility is hiring a warehouse manager with experience in managing a warehouse like yours.

The warehouse manager will monitor your employees’ daily jobs to ensure that stock is being properly scanned and cataloged. They’ll also frequently interact with your warehouse inventory system in order to keep an eye on your stock levels. Finally, the warehouse manager will be in charge of managing any difficulties that arise and act swiftly whenever your warehouse personnel detects an issue.

3. Establish a Workflow

After you have an organizational framework in place and a leader designated to oversee your warehouse operations, you’ll also need to implement a specific workflow. Your warehouse workflow should address how you receive new stock, where the new stock goes, and how it is tracked throughout the warehouse. You should also go over a number of operational issues with your warehouse manager, such as:

- Inventory tracking. This is a crucial component of inventory management since it enables employees to pick products from exactly the right area. Decide whether you need serial tracking, lot tracking, or a combination of both.

- Accounting methods like last in first out (LIFO), first in first out (FIFO), and weighted average method, are crucial to your warehouse management since most inventory software interfaces with accounting software to remove the possibility of human error and avoid the need for double entry.

- Inventory audits and cycle counting are crucial in order to prevent loss and have better control over your inventory. If inventory counts are not performed on a regular basis, units could be lost or stolen without your warehouse manager being aware of it.

4. Use Warehouse Management Software

Many tasks related to warehouse management can be automated with warehouse inventory management software. This software can instantly update the record of all stock on hand in real-time and display accurately all your stock and where it is located in the facility.

The information in the warehouse inventory management software will tell you which products should be counted and how frequently. In addition, when products reach a specified minimum amount, warehouse management software can be configured to automatically replenish stock. Efficient warehouse software solutions automatically evaluate past sales data to establish the ideal minimum amounts for automatic reordering and the quantities at which it should restock each item.

The Bottom Line

Even though warehouse operations are usually hidden from view by customers, they are a crucial component of on-time delivery.

The right warehouse inventory system can boost your warehouse operations’ efficiency, speed, and order accuracy while lowering operational expenses. This will help your business become more competitive and increase customer satisfaction.