The effectiveness of warehouse operations is crucial for a company’s success in the fast-paced world of modern business.

Due to the swift evolution of consumer demands and the worldwide expansion of supply chains, warehouses have transformed from mere storage spaces into crucial hubs that have a direct influence on customer happiness and corporate performance. Warehouse efficiency entails the maximization of different activities within a full warehouse operation, such as inventory control, storage, material handling, and information processing.

By optimizing efficiency, warehouses can make a substantial impact on expediting delivery times, improving inventory management, and reducing operating expenses, ultimately resulting in heightened customer satisfaction and business expansion.

The Significance of Optimizing Warehouse Operations

An effective warehouse management system is crucial for a successful supply chain. It involves the deliberate coordination of various processes, such as receiving, storing, selecting, and dispatching items.

Effective warehouse management software leads to cost reduction by decreasing waste and optimizing resource utilization, and it plays a pivotal role in customer satisfaction.

- Technological advancements: With the rise of technologies like automation, robotics, and AI, the warehouse landscape is undergoing significant changes. These advancements improve efficiency and reduce labor costs. For instance, the use of autonomous drones and collaborative mobile robots for inventory management is becoming more common, enhancing operational efficiency.

- Digital transformation: The acceleration of digital transformation in warehouses is evident. This includes the increasing use of warehouse management systems (WMS) which provide real-time data analytics for optimizing inventory levels and streamlining workflows.

- E-commerce fulfillment: The continued growth of e-commerce has made rapid order fulfillment a priority. Warehouses are adopting technologies and strategies like micro-fulfillment centers and advanced tracking systems to meet consumer demands for fast delivery.

- Omnichannel fulfillment: The shift towards omnichannel retailing has driven the adoption of WMS solutions that can synchronize inventory and fulfillment processes across various channels, meeting the increasing demand for a seamless shopping experience.

- Supply chain resilience: In response to recent global supply chain disruptions, there is a growing focus on resilience and flexibility. Warehouses are diversifying supplier bases and exploring alternative transportation routes to mitigate potential disruptions.

- Sustainability initiatives: Environmental concerns are prompting warehouses to adopt sustainable practices, such as using energy-efficient technologies and eco-friendly packaging materials.

- The human element: Despite technological advancements, the human aspect remains crucial. There is an emphasis on upskilling warehouse workers to adapt to new technologies and changing roles within the warehouse environment.

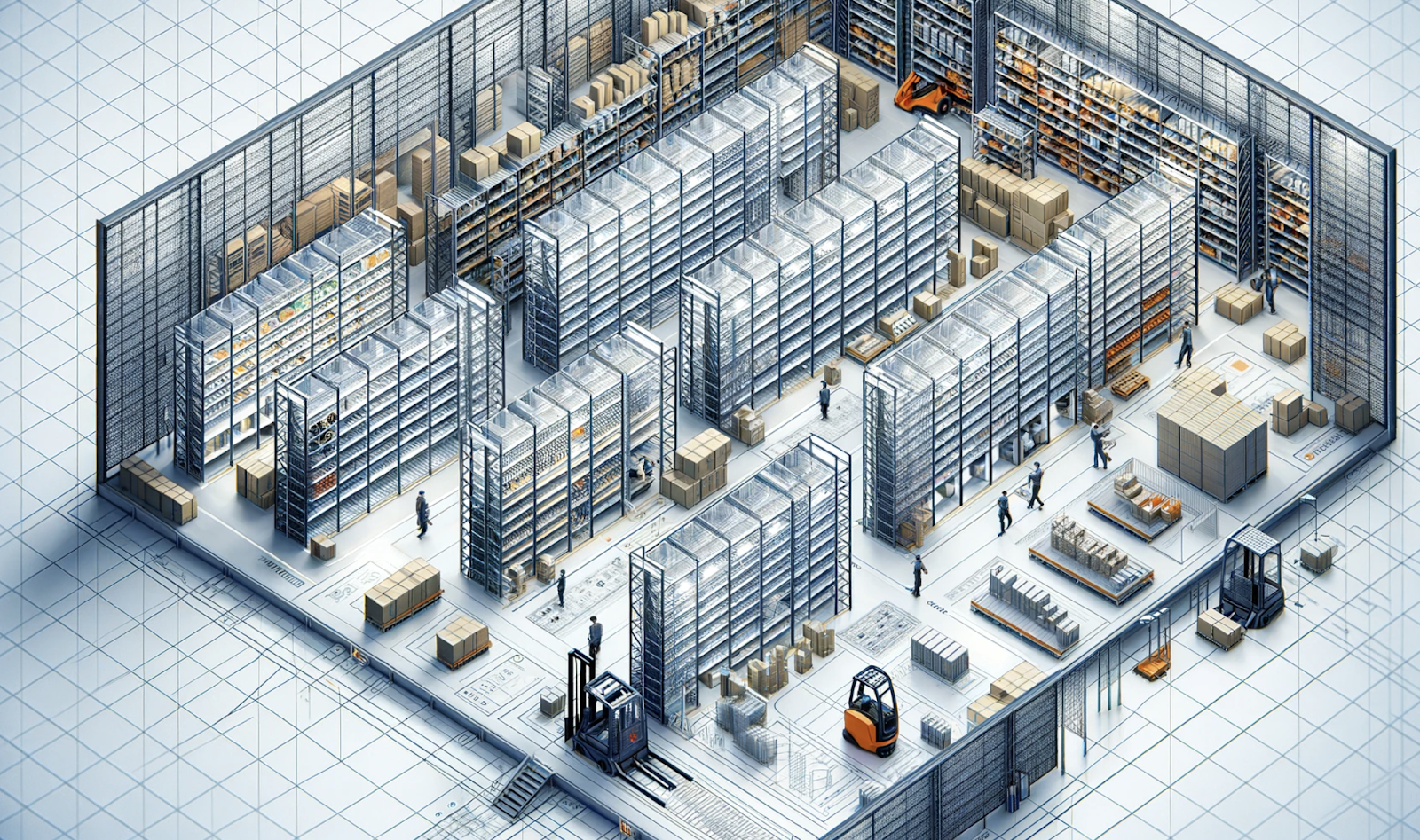

Optimizing Warehouse Operations Management Through Layout and Design Strategies

The arrangement and structure of a warehouse are essential factors that determine its overall productivity.

Optimizing the layout of warehouse space entails strategically positioning objects to expedite operations and maximize the utilization of space. Efficient shelving and aisle organization are crucial elements of this procedure. For example, it is advisable to position highly sought-after commodities in close proximity to the packing and shipping zones in order to minimize the time spent on transportation.

The aisle width should be tailored to accommodate the specific material handling equipment being used, ensuring effortless maneuverability. Moreover, maximizing vertical space by employing taller storage units can greatly enhance storage capacity, effectively utilizing the existing space to its fullest potential.

Utilizing Technology to Enhance Operational Efficiency

Integrating technology into warehouse operations has become important for preserving a competitive advantage.

Warehouse management systems and ERP systems are leading the way in this technological transformation.

These technologies provide immediate monitoring of inventory, optimize selection paths, and automate warehouse optimization plans and diverse administrative duties, resulting in improved efficiency and precision.

Moreover, the implementation of automated solutions, such as robotics and conveyor systems, can further enhance the efficiency of tasks such as sorting, picking, and packing.

Implementing Optimal Strategies for Managing Inventory

To enhance the flow of your content on efficient warehouse operations and inventory management, using linking words and phrases can create a more cohesive narrative. Here’s a revised version of your content:

Efficient warehouse operations are fundamentally anchored in effective inventory management. Employing strategies like just-in-time inventory, warehouses can optimize space utilization, thereby reducing holding costs and mitigating the risk of product obsolescence. Integral to this process are barcoding and RFID tagging, which serve as crucial tools for efficient and precise inventory tracking. These technologies offer immediate visibility into inventory levels, leading to more effective stock management.

Furthermore, precise demand forecasting, when combined with strategic inventory management, empowers warehouses to proactively anticipate client needs while minimizing unnecessary expenditures. In parallel, cycle counting emerges as a pivotal strategy for inventory accuracy. Unlike traditional physical inventories that necessitate operational halts, cycle counting is a continuous method that involves regularly counting a subset of inventory. This approach not only enables ongoing validation of inventory accuracy but also facilitates the prompt detection and rectification of discrepancies, thereby minimizing disruptions.

Additionally, the adoption of a tiered storage plan significantly bolsters inventory efficiency. This method involves categorizing inventory based on movement frequency and strategically placing frequently accessed items in easily reachable areas. Consequently, this reduces picking time and effort, markedly enhancing order fulfillment speed and accuracy.

The advancements in inventory management software have revolutionarily transformed stock management in warehouses. These contemporary systems are adept at integrating with forecasting tools, providing critical anticipatory insights regarding inventory requirements. They streamline processes by automating reordering tasks, tracking inventory across various locations, and suggesting optimal stock levels based on historical data and future projections.

And, the importance of interdepartmental collaboration in effective inventory management cannot be overstated. Seamless collaboration between procurement, sales, and warehousing teams ensures alignment of inventory levels with market trends and customer demand. This cross-functional approach is instrumental in avoiding the pitfalls of overstocking or understocking, thereby maintaining a balanced inventory that can adapt fluidly to market changes.

Adapting to Changing Market Trends and Customer Demands

In the fast-paced and dynamic world of logistics, adapting to changing market trends and customer demands is critical for optimizing warehouse operations. This adaptability isn’t just about handling increased volumes; it’s also about being able to quickly reconfigure operations to meet new requirements.

The rise of e-commerce, for instance, has led to a surge in small parcel shipments, requiring a shift from traditional bulk storage and distribution models. To maintain warehouse optimization, agility can be achieved through modular storage systems, flexible workforce management, and scalable technology solutions. By staying attuned to market shifts and customer preferences, warehouse managers can preemptively adjust their strategies and operations, thereby maintaining warehouse efficiency and competitiveness.

Leveraging Data Analytics for Insight-Driven Decision-Making

Data analytics is transforming how warehouses operate. By analyzing real-time data from various sources, warehouse managers can gain insights into operational inefficiencies, customer buying patterns, and potential areas for cost reduction.

Advanced analytics can help in predicting demand, optimizing inventory levels and warehouse processes, and identifying the most efficient shipping routes. This data-driven approach enables warehouses to make informed decisions, anticipate future trends, and continually refine their strategies for improved warehouse efficiency.

Environmental Sustainability in Warehouse Operations

Sustainability is becoming an increasingly important aspect of warehouse operations. Efficient warehouses not only contribute to profitability but also to environmental sustainability.

Measures such as energy-efficient lighting, solar power installations, and waste reduction initiatives not only reduce warehouse optimization trends and environmental footprints but can also lead to cost savings. Moreover, sustainable practices can enhance a company’s reputation and appeal to environmentally conscious consumers. Implementing green practices, therefore, is not just a corporate responsibility but also a strategic business decision.

Integrating Supply Chain Partners for Improving Warehouse Operations

Efficient warehouse operations are not isolated from the broader supply chain. Integration with suppliers, manufacturers, transporters, and retailers is crucial for seamless operations and timely delivery. This integration can be achieved through collaborative planning, shared data systems, and synchronized processes, addressing common challenges like shipping delays and stock control issues.

By working closely with supply chain partners, warehouses can improve their responsiveness, reduce lead times, and minimize disruptions due to human error or manual processes. Ongoing training and incentive pay for warehouse staff can further boost warehouse productivity. This collaborative approach ensures that the entire supply chain works cohesively, thereby enhancing the efficiency and effectiveness of warehouse operations and ultimately reducing customer dissatisfaction.

Future Trends in Warehouse Efficiency

Looking to the future, warehouses are likely to see more advancements in automation and robotics, which are key to improving warehouse design and operations. Drones for inventory purposes, autonomous vehicles for material handling, and AI-driven predictive maintenance are some of the emerging technologies that could redefine warehouse operations.

Additionally, the integration of Internet of Things (IoT) devices will further increase warehouse efficiency and enhance real-time monitoring and control of warehouse activities, helping to optimize workflows and manage available resources. ABC analysis and manual tasks will evolve with these technologies. They will not only improve operational efficiency but also open new avenues for innovation in warehouse management, catering to the needs of many businesses and further emphasizing the importance of warehouses in the supply chain.

Summary

Warehouse efficiency is a multi-faceted concept that extends beyond mere storage and distribution.

It encompasses a broad range of activities and strategies, all aimed at optimizing operations, reducing costs, and improving customer satisfaction. By embracing technological advancements, focusing on employee training and safety, adapting to market changes, leveraging data analytics, prioritizing sustainability, and integrating with supply chain partners, warehouses can achieve and sustain high levels of efficiency. As the business environment continues to evolve, so will the strategies and technologies to improve warehouse efficiency and productivity, making it an ongoing journey rather than a fixed destination.