Staying ahead in the fashion industry isn’t just about setting trends—it’s also about smart inventory management and supply chain efficiency. That’s where automated replenishment comes into play, a game-changer for the apparel industry.

Now, this innovative approach isn’t just a fancy tech upgrade; it’s a strategic tool reshaping how retailers stock up on their next bestsellers.

Before we unravel the layers of this amazing feature, let’s make sure we’re on the same page.

Let’s take a look at what automated replenishment actually is.

Brief Overview of Automated Replenishment

Automated replenishment is facilitated by tech – most commonly enterprise resource planning systems – to ensure that the right products are at the right place, at the right time, without manual intervention.

Having a proper auto-replenishment system in place will allow any brand to ensure its stock replenishment strategy is perfect.

So let’s check out automatic replenishment in-depth, one of the most amazing ERP features of today.

Pros of Automated Replenishment

Increased Accuracy and Reduction in Human Error

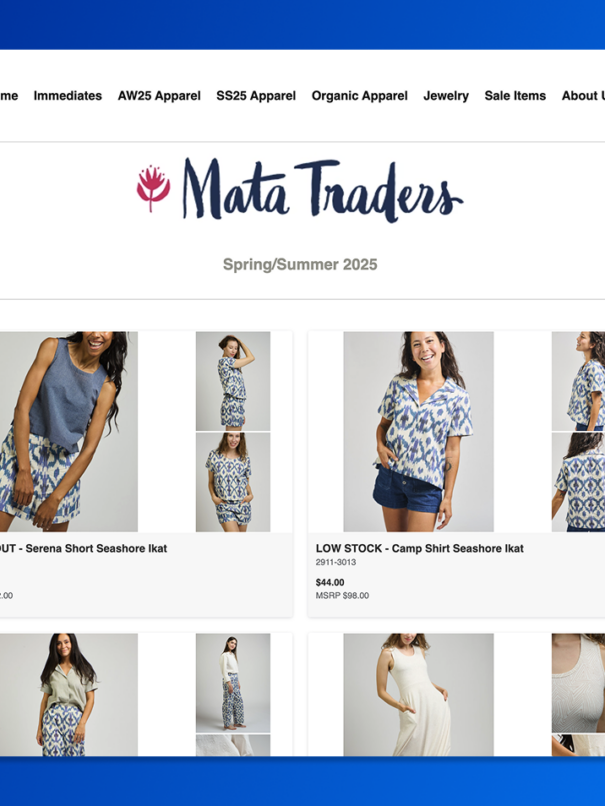

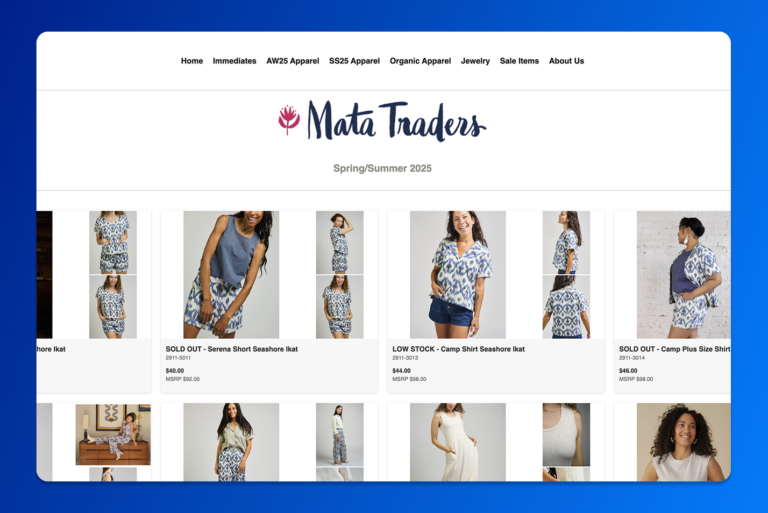

Automated replenishment solutions stand at the forefront of minimizing inaccuracies in inventory management. By integrating sophisticated algorithms and real-time tracking capabilities, these systems adeptly mitigate the risk of overstocking or understocking—common pitfalls in manual inventory management.

The precision of automated systems drastically lowers the incidence of human error, ensuring that inventory levels are meticulously balanced to meet demand without excess.

Enhanced Efficiency in Stock Management

Efficiency in stock management is significantly amplified through automation. Traditional methods, which rely on manual checks and balances, are not only time-consuming but also prone to delays in response to fluctuating stock levels. Automated inventory replenishment methods, on the other hand, offer a dynamic solution.

They continuously monitor existing stock levels and automatically trigger replenishment orders when supplies dip below predetermined thresholds. This seamless operation ensures that products are always available, enhancing customer satisfaction and loyalty.

Improved Demand Forecasting with Real-Time Data Analysis

One of the most transformative benefits of automated replenishment is its ability to forecast demand with remarkable precision. Utilizing advanced data analytics, this feature analyzes real-time sales data along with historical trends to predict future demand. This predictive capability allows retailers to adjust their inventory proactively, ensuring that they are well-stocked for upcoming trends and seasonal shifts. Moreover, by staying ahead of demand curves, retailers can optimize their inventory levels, minimizing wastage and maximizing sales potential.

Cost Savings

The economic advantages of automated replenishment cannot be overstated. By optimizing inventory levels, businesses can significantly reduce the costs associated with overstocking and stockouts. Furthermore, the reduction in manual labor required for inventory management translates into substantial cost savings.

The efficiency and accuracy of automated solutions also mean fewer lost sales due to stockouts and less capital tied up in excess inventory, contributing to healthier profit margins and a stronger bottom line.

Sustainable Inventory Practices

Sustainability has emerged as a critical focus area, with businesses adopting eco-friendly practices to align with consumer values and reduce environmental impact. This includes optimizing transportation routes, minimizing packaging waste, and embracing principles of the circular economy.

These sustainable practices not only cater to environmentally conscious consumers but also contribute to long-term cost savings .

The right ERP system allows for the automation of the inventory replenishment process but it also enables businesses to collaborate with vendors that are environmentally conscious and optimize their supply chains to adhere to their set sustainability objectives.

Cons of Automated Inventory Replenishment

The automated inventory replenishment feature offers numerous benefits for businesses by optimizing stock levels, improving efficiency, and reducing manual errors. However, there are several drawbacks and challenges to consider:

Possible Mismatches Between Automated Suggestions and Real-World Complexities

Automated systems use algorithms and data analysis to make replenishment recommendations. However, these suggestions might not always align with the nuances of current market trends or consumer behaviors. Algorithms can struggle to adapt to sudden changes in demand, unusual patterns, or external factors influencing buying behavior, leading to suboptimal stocking decisions.

Dependence on Technology

For the implementation of automated replenishment features, businesses can become heavily dependent on technology. This dependence increases the risk associated with system failures, software bugs, or data breaches. If the system experiences downtime or malfunctions, it can disrupt the entire supply chain, potentially leading to inventory shortages and lost sales.

But this can be easily avoided by picking the right ERP system.

Automated Replenishment Strategies

To maximize the benefits and minimize the drawbacks of automated inventory replenishment, businesses employ various strategies:

Reorder Point Strategy

This approach involves setting specific stock thresholds for each product. When inventory levels fall to these predefined points, the feature of the ERP system automatically triggers a reorder. This strategy helps maintain adequate stock levels to meet customer demand without overstocking.

Periodic Strategy

Under the periodic strategy, inventory levels are assessed at scheduled intervals—daily, weekly, or monthly—to inform bulk ordering. This approach can be simpler to manage but might not be as responsive to sudden changes in demand compared to real-time tracking methods.

Top-Off Strategy

The top-off strategy involves replenishing stock during slower periods or downtimes to prepare for upcoming peak sales times. This method ensures that there is always sufficient stock available when customer demand increases, without overburdening storage spaces during slower periods.

Demand Strategy

This strategy bases restocking levels on sophisticated demand forecasts that consider historical sales data, market trends, seasonal fluctuations, and other relevant factors. By predicting future demand with greater accuracy, businesses can optimize their inventory levels, reducing the risks of stockouts and excess inventory.

Each of these strategies has its strengths and can be chosen based on the specific needs and operational dynamics of the business. Effective inventory management often involves a combination of these approaches, tailored to align with the company’s goals, the nature of the products, and the patterns of demand.

Optimizing Auto Replenishment With ERP Systems

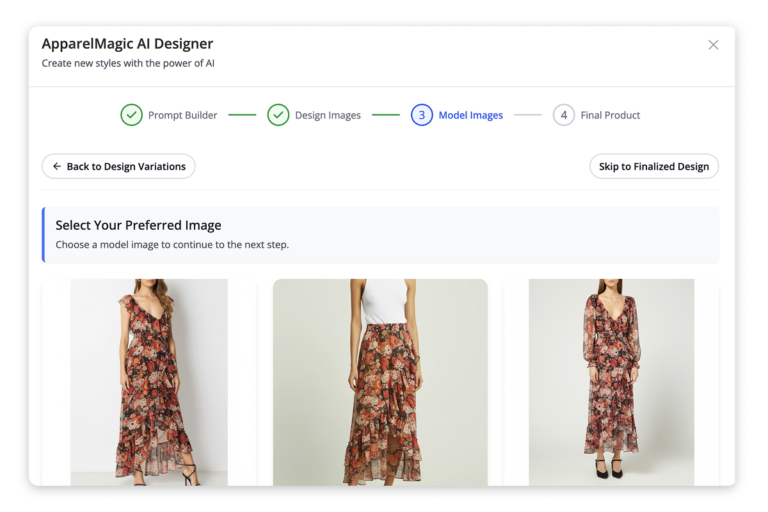

Optimizing automated replenishment within the fashion industry, especially when tailored by systems like ApparelMagic, reveals a nuanced approach that addresses the unique challenges and opportunities inherent in this dynamic sector. ApparelMagic, with its robust ERP, CRM, and PLM capabilities, is designed to cater specifically to the needs of the fashion industry, offering a comprehensive suite of tools that empower brands to manage their operations efficiently and scale effectively.

The key aspects that make ApparelMagic particularly suitable for optimizing automated replenishment in the apparel industry include its powerful automation functionalities, which streamline ordinary tasks like order handling, inventory management, and communication, allowing businesses to focus on strategic growth initiatives. Its inventory management capabilities are enhanced with AI for smart sales, accurate demand forecasting, and planning, ensuring brands can avoid overstocking or understocking and remain agile in a market that demands flexibility.

Furthermore, ApparelMagic’s ERP solutions are designed with a strong focus on sustainability, aligning with modern consumer demands for eco-friendly practices. This includes features that support the eco-friendly apparel revolution, such as managing eco-friendly materials and optimizing logistics to minimize emissions. The system also offers customization options to fine-tune various aspects of a business, from custom fields to reports, providing a tailored experience that meets the unique needs of each brand.

The integration of ApparelMagic with existing tools and platforms is seamless, enabling brands to expand their operational capabilities without significant disruptions. This ease of integration is crucial for maintaining the fluidity of operations and ensuring that businesses can leverage their existing investments in technology effectively.

Conclusion

The delicate decision to implement automated replenishment in the apparel industry involves taking a critical look at its pros and cons. While the initial costs and technological dependency pose challenges, the potential for increased accuracy, efficiency, and cost savings cannot be ignored. As with any technological adoption, strategic planning and a clear understanding of your business needs are crucial to leveraging automation effectively.