The manufacturing industry in 2024 presents plenty of challenges. From labor shortages to supply chain disruptions and the constant push for efficiency, the sector is under pressure to adapt. Fortunately, ERP, or enterprise resource planning, systems have become essential tools that manufacturers use to stay competitive and thrive.

With capabilities ranging from automation to real-time data insights, ERP systems are helping businesses solve manufacturing challenges, improve processes, and stay ahead in a demanding industry.

So let’s take a look at the manufacturing challenges solved by ERP solutions.

Minimizing Downtime with ERP: Addressing Labor Shortages

How ERP improves manufacturing processes is simple. Labor shortages continue to be one of the most critical hurdles for manufacturers in 2024. As businesses struggle to find skilled workers, ERP systems equipped with automation and AI are stepping in to fill the gaps.

Automating repetitive tasks like production scheduling, order processing, and inventory management reduces the need for a large workforce. AI further boosts efficiency by analyzing data to predict trends, demand forecasting, and identify bottlenecks. This allows companies to optimize their operations and make the most of the workforce they have.

For instance, AI-enabled ERP systems can anticipate equipment maintenance needs, helping manufacturers prevent downtime before it happens. By addressing labor shortages through automation, manufacturers can do more with fewer workers, which in turn, enhances overall productivity.

Managing Complex Supply Chains with Real-Time Visibility

Supply chains in 2024 are more complex than ever due to global disruptions, rising costs, and evolving consumer demands. Manufacturers need real-time visibility to ensure smooth operations, and this is where ERP software shines.

ERP systems offer a central hub for tracking every aspect of the supply chain—from raw material sourcing to delivery. By providing real-time updates, manufacturers can adjust quickly to delays, shortages, or transportation issues. Cloud-based ERP platforms, in particular, offer global access and scalability, allowing businesses to manage their supply chains across multiple locations.

For example, ERP systems can alert manufacturers when inventory levels are low, allowing them to reorder materials before a shortage impacts production. This kind of real-time visibility and automated decision-making not only boosts efficiency but also enhances customer satisfaction by minimizing delays.

Boosting Production Efficiency Through Integration

Production efficiency can make or break a business. Delays and downtime lead to lost revenue and missed opportunities, which is why integrating ERP systems into manufacturing operations is essential.

ERP systems offer integrated solutions that cover the entire production cycle—from procurement to final quality checks. Real-time data from the production line allows manufacturers to spot inefficiencies, such as equipment bottlenecks or underperforming shifts, and adjust quickly. ERP improves manufacturing processes by providing insights into material usage, equipment performance, and workforce productivity.

Predictive analytics, an essential feature of modern ERP systems, also helps manufacturers foresee potential disruptions and take preventive measures. This proactive approach reduces the risk of unexpected downtime, keeps production running smoothly, and ensures deadlines are met.

Streamlining Regulatory Compliance

Manufacturers must comply with a wide range of regulations, from environmental standards to product safety laws. Compliance can be time-consuming and costly, but ERP systems make it much easier by automating the tracking and reporting of regulatory data.

With built-in compliance tools, ERP systems can generate real-time reports, ensuring that manufacturers meet industry standards without manual oversight. Whether it’s tracking emissions for environmental regulations or ensuring product safety certifications, ERP systems automate these processes, minimizing the risk of non-compliance.

This automation not only saves time but also allows manufacturers to focus on other aspects of their business, like improving product quality and enhancing customer service. In short, ERP systems streamline compliance efforts, helping businesses avoid costly fines and stay competitive.

Improving Equipment Efficiency and Minimizing Downtime

Equipment downtime is a significant drain on resources, with some industries losing millions in revenue from even a few hours of halted production. Minimizing downtime with ERP systems is critical to maintaining productivity.

ERP systems with integrated asset management tools monitor equipment performance and schedule preventive maintenance. By keeping tabs on the condition of machinery, manufacturers can address issues before they result in costly breakdowns. Predictive maintenance, driven by AI, takes this a step further by using historical data to predict when equipment is likely to fail.

The result? Less downtime, fewer emergency repairs, and a more efficient production process. By improving equipment efficiency, manufacturers can maximize uptime, enhance production schedules, and ensure they meet customer deadlines.

Optimizing Inventory Management with Real-Time Insights

Inventory management can be a balancing act for manufacturers. Too much inventory ties up capital, while too little can lead to production delays. ERP systems solve this problem by providing real-time insights into inventory levels, production needs, and customer demand.

ERP systems use predictive analytics to forecast demand, helping manufacturers align production schedules with market needs. This minimizes excess inventory and reduces waste, leading to cost savings and improved cash flow.

In addition, ERP systems streamline the supply chain by ensuring that raw materials and finished goods are available when needed. With real-time inventory tracking, manufacturers can avoid shortages and overproduction, optimizing their resources and improving customer satisfaction.

Enhancing Cybersecurity in an Increasingly Digital World

As manufacturers continue to digitize their operations, cybersecurity becomes more critical than ever. The risk of cyberattacks on manufacturing systems, especially ERP platforms, has grown as more companies adopt digital tools.

Modern ERP systems are designed with robust cybersecurity measures, including encryption, multi-factor authentication, and real-time monitoring. These tools ensure that sensitive data, from intellectual property to customer information, is protected from breaches. By securing both operational and financial data, ERP systems help manufacturers mitigate cyber risks and maintain business continuity.

The Rise of Modular and Cloud ERP Solutions

Another in line with the manufacturing challenges solved by ERPs is enabling manufacturers to pick and choose the functionalities they need—whether it’s supply chain management, financial reporting, or inventory control.

Cloud ERP systems are also on the rise, offering scalability and lower infrastructure costs. Cloud-based ERP allows manufacturers to access critical data from any location, ensuring that they can manage their operations seamlessly, even across multiple facilities.

These cloud-based systems are particularly useful for manufacturers with global supply chains, as they offer real-time data access, collaboration, and flexibility. As a result, manufacturers can make faster decisions, improve coordination, and minimize downtime, all while reducing the costs associated with on-premise infrastructure.

How ApparelMagic Helps Apparel Manufacturers

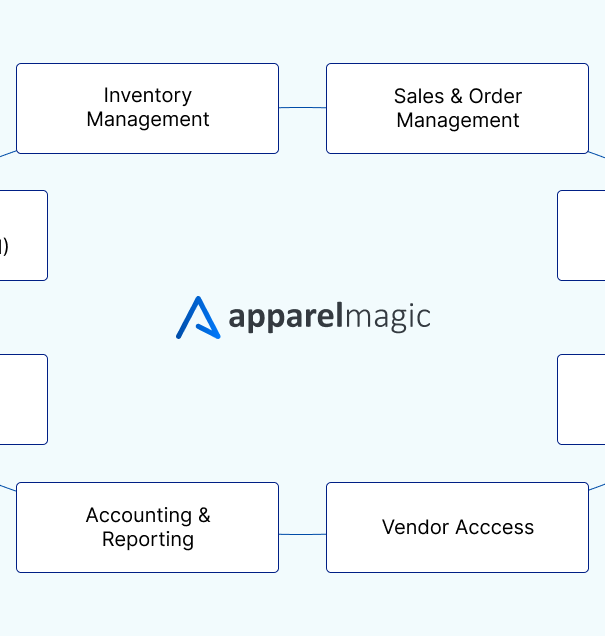

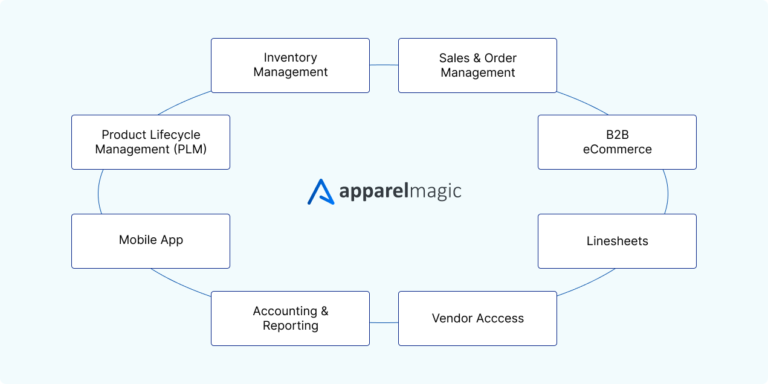

ApparelMagic allows manufacturers to manage complex inventories in real time. It tracks thousands of SKUs with variations like size and color across multiple channels. This ensures that inventory levels are accurate and well-managed, reducing the risk of stockouts or excess stock.

Product Lifecycle Management (PLM) & Production Optimization

In the fast-paced fashion industry, staying ahead of trends is vital. ApparelMagic integrates Product lifecycle management (PLM), allowing manufacturers to oversee the entire product creation process, from design concept to finished product. By centralizing data, ApparelMagic helps streamline design approvals, material sourcing, and production timelines.

- Key benefit: Improved collaboration between design and production teams leads to quicker time-to-market, while also ensuring that quality standards are met throughout the lifecycle of each product.

Multi-Channel Sales Integration

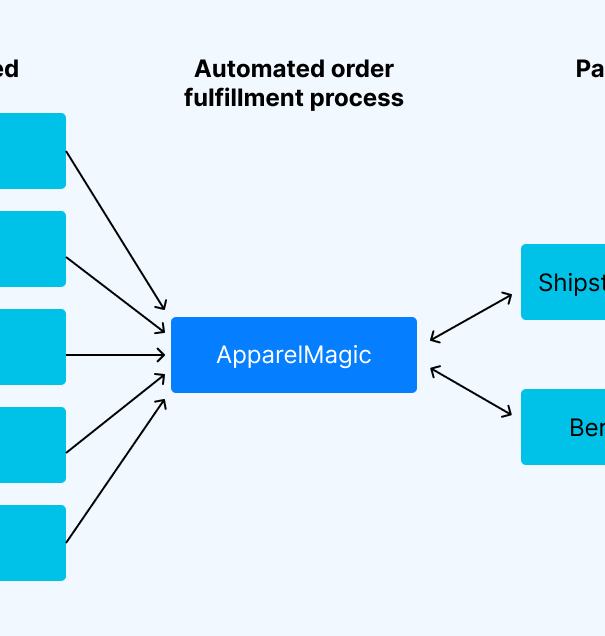

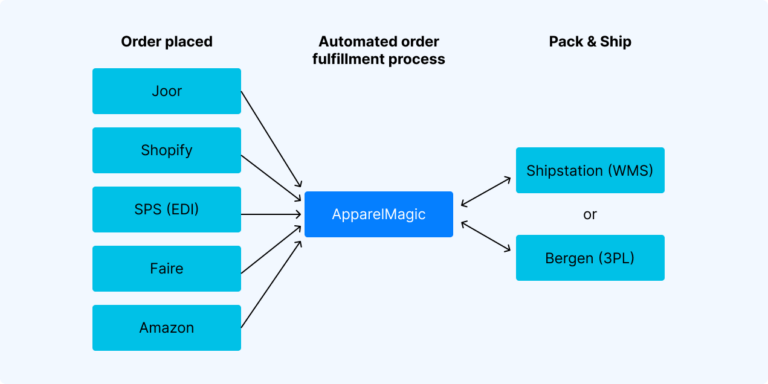

Selling apparel today often involves a mix of brick-and-mortar stores, e-commerce platforms, and wholesale channels. ApparelMagic’s multi-channel sales integration enables manufacturers to manage orders seamlessly across various platforms like Shopify, Amazon, and B2B portals. This synchronization means that stock levels, orders, and returns are updated in real time, eliminating the need for manual adjustments and preventing overselling.

- Key benefit: This multi-channel approach helps manufacturers maximize revenue by optimizing order management, while also providing better customer service by ensuring orders are fulfilled accurately and on time.

Comprehensive Financial and Accounting Tools

Financial management in manufacturing goes beyond simple bookkeeping. ApparelMagic provides multi-currency financial tracking, profit margin analysis, and detailed cost management tools. Manufacturers can easily track costs related to production, shipping, and raw materials, ensuring a clear understanding of profitability at every stage.

- Key benefit: The system supports global transactions, enabling businesses to operate seamlessly in international markets while staying on top of their financial health. With in-depth financial reports, manufacturers can make data-driven decisions that improve their bottom line.

Order Management and Fulfillment

Order management is one of the most critical areas in apparel manufacturing. ApparelMagic offers robust tools to track orders from placement to fulfillment, automating tasks like invoicing, shipping, and customer updates. This reduces manual errors and ensures that orders are fulfilled quickly and accurately, leading to higher customer satisfaction and repeat business.

- Key benefit: Automated order management reduces administrative work and ensures that your production schedules are aligned with demand, which is essential for maintaining profitability.

Wrap Up

Manufacturing businesses face unprecedented challenges, but an ERP system can offer solutions to navigate these complexities.

From addressing labor shortages with AI and automation to providing real-time visibility into supply chains, ERP tools streamline operations and improve efficiency. Whether it’s optimizing inventory, boosting cybersecurity, or ensuring regulatory compliance, ERP systems empower manufacturers to stay competitive in an ever-evolving landscape.

For industries like apparel manufacturing, specialized solutions like ApparelMagic further enhance production, financial management, and order fulfillment. So, take note of the manufacturing challenges solved by ERP and change the way you operate for the better today.